In the refrigeration industry, small material changes often reflect major shifts in manufacturing philosophy. The evolution of aluminum foil tape used in refrigerators and freezers is a clear example. Once a simple auxiliary material applied manually, aluminum foil tape has now become a key functional component optimized for automated production lines, energy efficiency, and environmental responsibility. This transition—particularly the shift from liner-backed aluminum foil tape to linerless aluminum foil tape—has quietly but significantly reshaped the way modern refrigeration equipment is manufactured and how it performs in real-world use.

From Manual Application to Automated Production

Traditionally, aluminum foil tape used in refrigerators and freezers was supplied with a release liner (backing paper). This format was well suited for manual application: workers could peel off the liner and apply the tape precisely where needed, such as sealing insulation joints, covering gaps, or reinforcing vapor barriers.

However, as refrigerator and freezer manufacturing has become increasingly automated, manual tape application has gradually been replaced by direct machine application. On automated production lines, liner-backed tapes introduce several inefficiencies.

-

Additional steps are required to remove the liner

-

Increased risk of jamming or misalignment

-

Extra waste that must be collected and processed

To address these challenges, manufacturers have shifted toward linerless aluminum foil tape. In this format, the adhesive surface is treated with a release coating or engineered to unwind smoothly from the roll without sticking. This change allows the tape to be fed directly into automated equipment, improving line speed and application consistency.

Why Linerless Aluminum Foil Tape Offers Clear Advantages

1. Improved Manufacturing Efficiency

In high-volume refrigerator and freezer production, every second matters. Linerless aluminum foil tape eliminates the need for liner removal, enabling machines to apply tape continuously and accurately. This reduces downtime, lowers labor requirements, and improves overall production efficiency.

For manufacturers operating multiple assembly lines, the cumulative efficiency gains are substantial. Faster production speeds also result in more consistent application quality, which directly affects product performance and durability.

2. Reduced Waste and Environmental Impact

Release liners may seem insignificant, but when thousands or even millions of meters of tape are used each year, the resulting waste quickly accumulates. Liner paper is typically discarded immediately after application and is not always easy to recycle.

By switching to linerless aluminum foil tape, refrigerator and freezer manufacturers significantly reduce solid waste. This aligns with broader industry efforts to lower environmental impact, reduce pollution, and comply with increasingly strict sustainability requirements.

Functional Role of Aluminum Foil Tape in Refrigerators and Freezers

Beyond manufacturing efficiency, aluminum foil tape plays a critical functional role within refrigeration systems. Its performance directly influences energy efficiency, moisture control, and long-term reliability.

Superior Thermal Insulation and Reflectivity

Aluminum foil tape features a bright aluminum surface that reflects more than 95% of radiant heat. When applied to insulation joints or seams inside refrigerator and freezer cabinets, this reflective surface helps minimize heat transfer.

In practical terms, this leads to:

-

Reduced energy loss

-

More stable internal temperatures

-

Lower load on compressors and cooling systems

When used in combination with foam insulation, aluminum foil tape enhances overall thermal performance without adding bulk or weight.

Effective Moisture and Vapor Barrier

Moisture is one of the greatest threats to refrigeration insulation materials. Water vapor penetration can degrade insulation performance, reduce thermal efficiency, and eventually lead to corrosion or mold issues.

The impermeable aluminum foil layer serves as a reliable barrier against:

-

Water vapor

-

Oxygen

-

Corrosive gases

By sealing joints, gaps, and penetration points, aluminum foil tape helps maintain the integrity of the insulation system throughout the product’s service life.

Durability Under Harsh Operating Conditions

Refrigerators and freezers operate under demanding conditions, including temperature fluctuations, humidity, and long-term continuous use. Aluminum foil tape is well suited to these environments.

Weather and Chemical Resistance

High-quality aluminum foil tape resists:

-

Ultraviolet exposure

-

Ozone

-

Moisture

-

Many chemicals commonly found in industrial environments

Acrylic adhesive versions, in particular, offer excellent aging resistance, maintaining stable adhesion even after years of operation. This durability is especially important in commercial freezers, cold storage equipment, and industrial refrigeration systems.

Flexibility and Conformability

Despite its metallic appearance, aluminum foil tape is soft and highly flexible. It easily conforms to curved surfaces, corners, and irregular contours inside refrigerator cabinets, as well as around pipes and air ducts.

This flexibility allows the tape to:

-

Effectively seal narrow gaps

-

Wrap tightly around joints and transitions

-

Maintain adhesion without cracking or lifting

As a result, reliable sealing performance is achieved even in complex assembly areas.

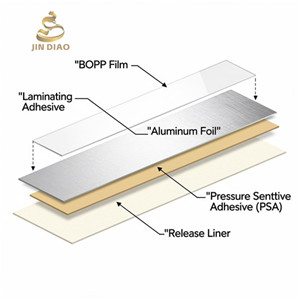

Design Considerations: Release Coatings and Laminated Structures

Modern aluminum foil tape is available in multiple configurations to meet different application requirements:

-

Release-coated adhesive backing: The adhesive surface is treated with a release agent, allowing smooth unwinding without a liner.

-

PET & BOPP laminated aluminum foil tape: Through a composite structure, PET and BOPP laminated aluminum foil tape significantly improves tensile strength, effectively reducing the risk of foil breakage caused by excessive mechanical tension during automated production. This design enhances physical durability while optimizing material cost, without compromising the aluminum foil’s high reflectivity and efficient thermal conductivity.

-

Laminated release paper or film: Used when manual application or precise positioning is required.

For automated refrigerator and freezer production, release-coated linerless tapes are increasingly preferred. They offer a balanced solution in terms of ease of use, performance, and sustainability.

Manufacturers selecting aluminum foil tape should consider factors such as adhesive type, temperature resistance, and compatibility with automated equipment. Working with experienced suppliers helps ensure that the tape meets both production and performance requirements.

Overview of Industry Applications

In practical refrigerator and freezer manufacturing, aluminum foil tape is commonly used for:

-

Sealing insulation board joints

-

Covering foam injection holes

-

Reinforcing vapor barriers

-

Wrapping cooling pipes and air ducts

-

Preventing condensation on cold surfaces

As production technologies evolve, aluminum foil tape is no longer merely an auxiliary material but an integral part of system design and energy management.

For more detailed product information and application options, aluminum foil tape designed specifically for industrial and refrigeration use is widely available.

Conclusion

The transition from liner-backed aluminum foil tape to linerless aluminum foil tape reflects a broader transformation in refrigerator and freezer manufacturing. Driven by automation, sustainability, and performance requirements, this shift delivers tangible benefits: higher efficiency, reduced waste, and improved product reliability.

At the same time, the core advantages of aluminum foil tape—thermal reflectivity, moisture resistance, durability, and flexibility—remain essential to modern refrigeration systems. As manufacturers continue to optimize production processes and product performance, aluminum foil tape will remain a critical behind-the-scenes component in the refrigeration industry.

https://www.cn-aluminumtape.com/

JIN DIAO