Aerial Working Platforms (AWPs), also known as elevating work platforms or mobile elevating work platforms (MEWPs), are indispensable in industries such as construction, maintenance, logistics, and warehousing. These platforms are required to provide safe, stable, and flexible elevation capabilities for operators performing tasks at heights. At the core of these systems lies the slewing drive – a crucial component that enables the rotational motion of the platform. In this blog post, as a high performance slew drive manufacturer, YOJU will share the benefits of open housing slewing drive for aerial working platform.

1. Introduction to Open Housing Slewing Drive for sale

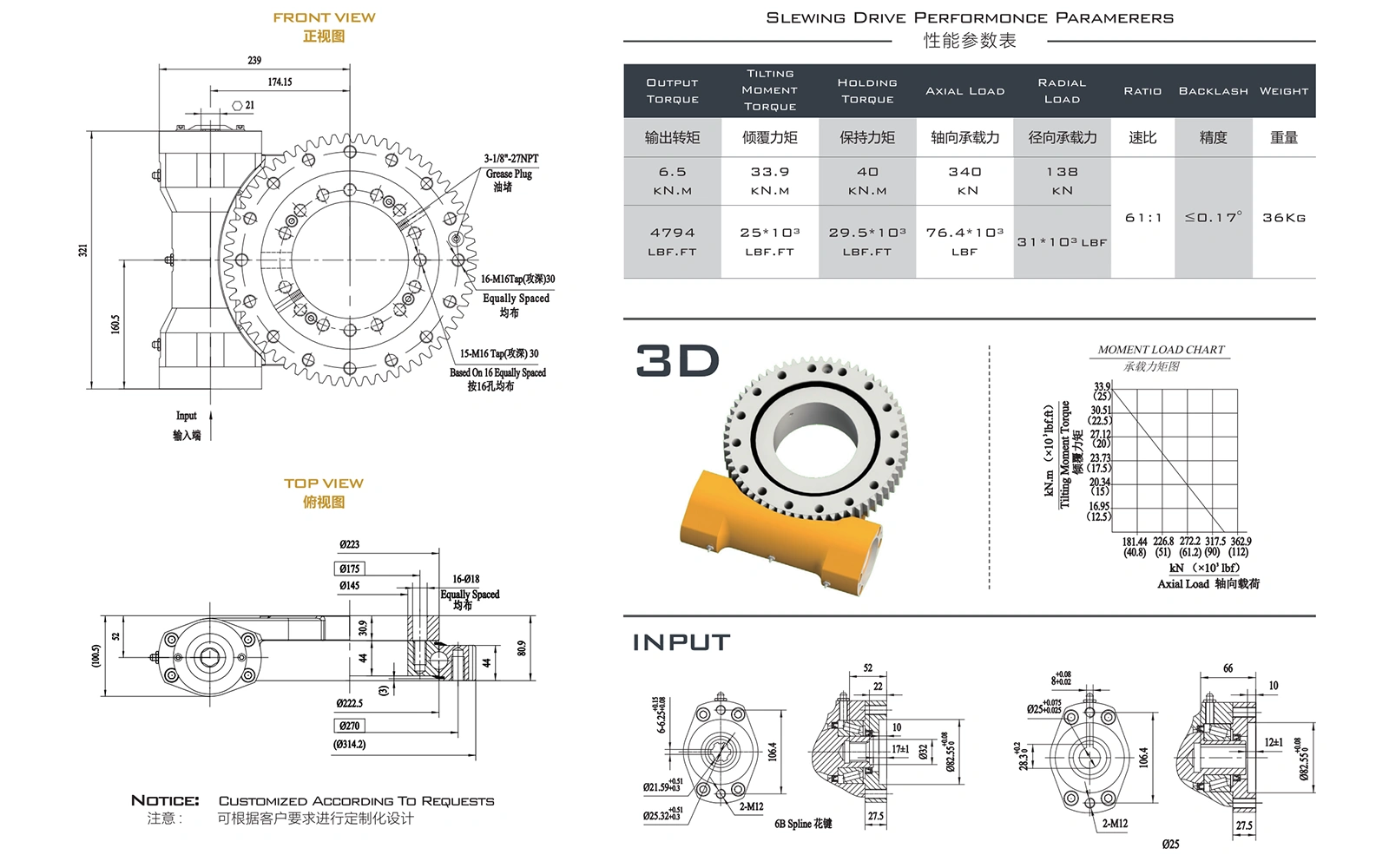

Slewing drives are gear mechanisms that handle axial and radial loads and transmit torque for rotational movement. Open housing slewing drives, unlike their enclosed counterparts, have an exposed gear set, typically consisting of a slewing ring and a worm gear. While open to the environment, these drives are engineered for high visibility, ease of maintenance, and flexibility in customized applications.

In aerial working platforms, the slewing drive is responsible for the rotational movement of the basket or boom around the vertical axis. This rotary motion allows the platform to provide a full range of motion and greater accessibility for tasks performed at heights. The decision to use an open housing design over a closed housing design depends on a variety of application-specific parameters, and open housing slewing drives provide a compelling array of advantages in the context of AWPs.

2. Structural Simplicity and Compact Design

One of the primary benefits of the open housing slewing drive is its structural simplicity. The absence of a fully enclosed casing makes the component lighter and more compact, which is particularly advantageous for aerial working platforms where minimizing weight and optimizing space are critical.

The compact footprint of open housing slewing drives allows for better integration into limited installation areas, such as in the rotating mechanisms of articulating booms or telescopic platforms. This directly contributes to better vehicle maneuverability and reduced fuel or battery consumption, especially in electric or hybrid AWPs.

3. Ease of Inspection and Maintenance

A major advantage of open housing designs is the improved ease of access for inspection and maintenance. Unlike enclosed slewing drives that may require partial disassembly for routine checks, open housing units provide direct visibility and physical access to the gear teeth, worm shaft, and bearings.

This facilitates faster maintenance routines, which is especially valuable in time-sensitive operations such as infrastructure repair or emergency services. Additionally, the ability to visually inspect gear wear, lubrication levels, and potential damage without the need to open a sealed housing results in improved operational safety and reduced downtime.

4. Cost-Effectiveness and Customization

From a manufacturing standpoint, open housing slewing drives are generally less expensive to produce due to the reduced need for casing materials, sealing systems, and additional machining processes. This makes them an attractive choice for budget-conscious AWP manufacturers without compromising on performance.

Moreover, open housing slewing drives offer greater flexibility in customization. Their exposed design allows engineers to modify gear ratios, shaft dimensions, and load-bearing configurations more easily to suit specific platform requirements. This is particularly beneficial in custom-built aerial work platforms for specialized industries such as oil & gas, telecommunications, or firefighting.

5. Enhanced Cooling and Lubrication Control

Thermal management is often an overlooked but critical aspect of slewing drive performance. The open housing configuration naturally allows better air circulation around the gear components, which helps dissipate heat more effectively during prolonged or heavy-duty operation.

In high-load or continuous rotation scenarios – such as when an aerial platform is used for prolonged inspection or painting tasks – the open design ensures that heat buildup does not degrade the performance or lifespan of the drive. Additionally, the user can manually apply or replenish lubrication more precisely and frequently, tailoring the lubrication method to the duty cycle and environmental conditions.

6. Superior Load Distribution and Torque Transmission

Despite the lack of an enclosed housing, modern open slewing drives are engineered with high-strength materials and precision manufacturing techniques that allow them to deliver excellent load distribution and torque transmission. The worm gear mechanism in the slewing drive creates a self-locking system, which enhances safety by preventing unintentional platform movement when power is off or under emergency stop conditions.

Furthermore, the use of optimized gear teeth geometry and high-precision machining ensures that contact stress is minimized, and torque is transmitted with high efficiency. This translates into smoother rotation, better control, and longer mechanical life – all of which are desirable attributes in aerial working platforms that operate under varying load and speed conditions.

7. Versatility in Environmental Conditions

Open housing slewing drives can be adapted with surface treatments, coatings, or materials that suit a variety of environmental conditions. In dusty or muddy terrains, such as construction sites, an open housing design can be advantageous because it allows contaminants to be easily washed off or removed, whereas in closed units, debris may accumulate within the housing and cause premature failure.

Additionally, when combined with corrosion-resistant materials or treated surfaces, open housing slewing drives can function effectively in coastal or offshore environments. This adaptability makes them suitable for AWPs used in a wide range of industries and climates.

8. Integration with Manual or Motorized Actuation

Another advantage of the open housing slewing drive is its ease of integration with either manual or motorized actuation systems. For lightweight or compact AWPs, the drive can be manually operated via a hand crank or lever system. Conversely, for larger or higher-reach models, it can be seamlessly connected to hydraulic, electric, or pneumatic motors for automated control.

This adaptability allows AWP designers to offer different models or configurations based on customer needs without redesigning the entire rotational mechanism. It also simplifies the retrofit or upgrade of older platforms with new drive technologies.

9. High Safety and Operational Reliability

Safety is paramount in aerial working platforms, and the slewing drive contributes directly to operator security. Open housing slewing drives provide dependable mechanical locking due to the inherent self-locking characteristics of the worm gear. This feature prevents the rotation of the platform unless actively driven, thereby reducing the risk of accidental movement during operator use or platform loading.

Furthermore, the simplicity and visibility of the open gear train enhance the ability to identify and address potential issues proactively, thus contributing to higher overall system reliability and lower total lifecycle costs.

10. Compatibility with Digital Feedback Systems

With the increasing digitization of construction and maintenance equipment, many AWPs are being integrated with smart systems for real-time monitoring and control. Open housing slewing drives can be equipped with encoders or torque sensors more easily than enclosed units, thanks to the accessible layout.

This allows for advanced features such as position tracking, torque monitoring, and remote diagnostics – capabilities that are becoming standard in high-end aerial platforms. These feedback systems enhance operational precision and enable predictive maintenance strategies.

Conclusion

Open housing slewing drive offers a strategic combination of performance, accessibility, and economy for aerial working platforms. Its design advantages – including ease of inspection, high torque output, lightweight structure, and compatibility with hydraulic or electric systems – make it a compelling choice for manufacturers and operators alike!

www.enyoju.com

YOJU