In today’s technologically advanced world, electronic components play a vital role in powering our devices, from smartphones and laptops to cars and home appliances. Have you ever wondered how these intricate components are made? In this blog post, we will delve into the fascinating process of manufacturing electronic components, exploring the various stages and technologies involved.

- Design and Prototyping:

The journey of electronic component manufacturing begins with meticulous design and prototyping. Engineers and designers work closely to conceptualize and create the blueprint of the component, considering factors like functionality, size, and performance. Computer-aided design (CAD) software is used to model and simulate the component, ensuring its compatibility with the intended application. - Material Selection and Preparation:

Once the design is finalized, the next step is selecting the appropriate materials for the component. Different materials possess unique electrical, thermal, and mechanical properties, influencing the component’s performance. Common materials include silicon, copper, aluminum, and various types of polymers. These materials undergo rigorous testing and quality control procedures to ensure their reliability and suitability for the intended purpose. - Fabrication Techniques:

Electronic components are manufactured using a variety of fabrication techniques, each tailored to the specific component type. Let’s explore some of the most commonly used techniques: a. Integrated Circuit (IC) Manufacturing:

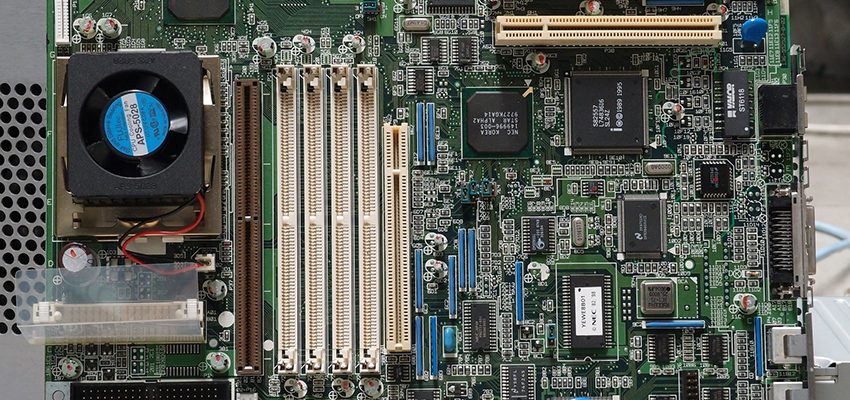

ICs, the building blocks of modern electronics, are produced through a complex process called semiconductor fabrication. This involves creating multiple layers of conductive, insulating, and semiconducting materials on a silicon wafer using techniques like photolithography, etching, and deposition. b. Printed Circuit Board (PCB) Manufacturing:

PCBs serve as the foundation for electronic components, providing electrical connections between various elements. The manufacturing process involves etching a copper-clad laminate board to create conductive pathways, followed by drilling holes for component placement and soldering. c. Passive Component Manufacturing:

Passive components, such as resistors, capacitors, and inductors, are typically manufactured using techniques like thin-film deposition, ceramic sintering, and wire winding. These processes ensure precise control over the component’s electrical properties. - Assembly and Testing:

Once the individual components are fabricated, they undergo assembly and testing to create functional electronic devices. Advanced robotic assembly systems are employed to precisely place and solder components onto PCBs, ensuring optimal electrical connections. After assembly, rigorous testing procedures, including functional testing, electrical testing, and quality control checks, are conducted to ensure the components meet the required specifications.

Conclusion:

The manufacturing of electronic components is a highly intricate and precise process, involving cutting-edge technologies and meticulous attention to detail. From the design and prototyping stage to material selection, fabrication techniques, and final assembly, every step contributes to the creation of reliable and high-performance components. Understanding this journey helps us appreciate the complexity behind the electronic devices we rely on daily.