Using an electric pressure cooker to prepare meals saves time and effort, but many users encounter the issue of "air leakage around the cooker" — a problem that not only affects cooking efficiency and prevents food from cooking properly but could also pose safety risks.

In most cases, air leakage issues are related to several key components. There's no need to rush for repairs. By following the step-by-step inspection method outlined below, you will likely be able to resolve the issue on your own.

Today, we will share with you the detailed inspection and troubleshooting methods! Important Note: Before starting the inspection, always unplug the cooker, and ensure the pot has completely cooled down and there is no internal pressure before proceeding. Safety first!

1. Inspect the Sealing Ring

Start with the sealing ring, which is the most common cause of air leakage. The sealing ring (also known as the gasket) is a critical component that forms the seal. It functions as a "barrier" that tightly fits between the cooker body and the lid, preventing steam from leaking out.

If the sealing ring is damaged, air leakage is almost inevitable, making it the primary cause of leakage around the cooker.

Inspection Method:

1. Visual Inspection: Remove the sealing ring from the groove on the lid and carefully inspect the surface for any cracks, chips, signs of aging (e.g., yellowing), or visible wear and deformation (e.g., dents or bulges).

2. Elasticity Test: Gently pull the sealing ring and check its elasticity. If it feels hard, or if it doesn’t quickly return to its original shape after being stretched or pressed, the elasticity has deteriorated.

3. Cleanliness Check: Check for food residue, oil stains, or accumulated debris on both the sealing ring surface and the groove of the lid. These impurities can interfere with the seal and potentially cause false air leakage.

Solution:

1. If there are residues or oil stains, clean the sealing ring and the groove thoroughly with warm water and a mild detergent using a soft brush, then dry it before reinstalling.

2. If the elasticity has decreased but there are no cracks, soak the sealing ring in 40°C water for 10-15 minutes to soften the rubber, temporarily restoring its elasticity (this is a temporary fix; replacing the ring is recommended for long-term use).

3. If there are cracks, chips, or a complete loss of elasticity, replace the sealing ring with a new one of the same model (ensure compatibility with your cooker’s brand and model, as sizes vary).

2. Inspect the Steel Ring (Supporting Component for the Sealing Ring)

Don’t overlook the steel ring beneath the sealing ring. This steel ring is a key component that supports the sealing ring, ensuring it maintains its correct shape and provides a better seal.

The steel ring has a distinct front and back. If installed incorrectly, it can cause uneven pressure on the sealing ring, preventing it from fitting tightly and causing air leakage.

Inspection Method:

Remove the sealing ring, and you will see the steel ring beneath it. Observe the steel ring’s shape: it typically has a raised side and a flat (or concave) side. The correct installation method is to have the raised side facing up, which ensures it supports the sealing ring evenly.

If the raised side is facing down, the steel ring is installed incorrectly.

Solution:

Remove the steel ring, reverse it so that the raised side faces up, and reassemble the sealing ring to ensure it is properly installed without any misalignment or wrinkles.

3. Inspect the Inner Pot for Deformation (Oval Shape) and Check the Height Relative to the Middle Layer

The inner pot is the component that holds the food and also needs to form a sealing space with the lid and middle layer. If the inner pot is deformed or if its height relative to the middle layer does not meet the standards, it will damage the seal and allow steam to leak out.

Inspection Method:

1. Check for Oval Shape:

• Remove the inner pot and place it on a flat surface (table or floor). Gently rotate the inner pot.

• If the pot wobbles noticeably or if there is an uneven gap between the pot edge and the surface, it is likely deformed (probably oval-shaped).

• Alternatively, measure the inner pot’s diameter at different positions. If the measurements are inconsistent, the pot is likely oval-shaped.

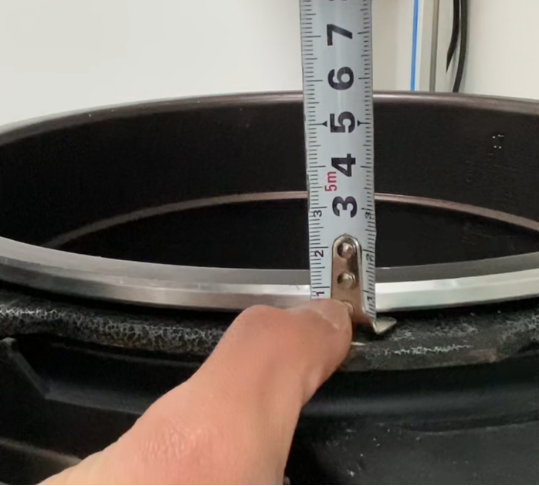

2. Check the Height Relative to the Middle Layer:

• Place the inner pot in the pressure cooker and observe the distance between the top edge of the inner pot (the silver edge) and the middle layer. The standard gap should be between 1.4 and 1.6 cm.

• If the gap is smaller than 1.2 cm, or if the top edge of the inner pot is below the middle layer, the inner pot has likely undergone "concave" deformation, often due to prolonged high-temperature use, collisions, or carrying heavy objects.

Solution:

1. For mild deformation (slightly oval or concave): Gently correct the shape by hand (apply light pressure to avoid breaking the pot). After correction, place it back into the cooker to check if the deformation affects the seal. If it doesn’t, you can continue using it.

2. For severe deformation (clearly oval or deeply concave): It’s not recommended to continue using the pot. A deformed pot not only has a poor seal but may also be unsafe, as uneven pressure during heating can lead to further damage. Replace it with a new, original pot of the same model.

4. Inspect the Heating Plate for Deformation

The heating plate is responsible for heating the cooker and also serves as the "base" supporting the inner pot. If the heating plate is deformed (uneven), it can cause the inner pot to sit unevenly, leading to improper sealing between the pot and the lid, resulting in air leakage.

This issue is less common but should still be checked if other solutions do not resolve the problem.

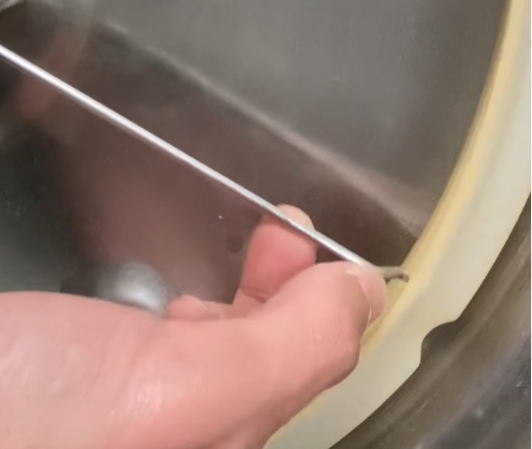

Inspection Method:

Unplug the cooker and allow the heating plate to cool down. Then, visually inspect the surface of the heating plate for any obvious deformities.

You can also use a straight ruler (or a flat card) to place at various points on the heating plate (horizontally, vertically, and diagonally). Check for any gaps between the ruler and the plate. If noticeable gaps appear, the heating plate is deformed.

Solution:

Heating plate deformation is usually caused by prolonged high temperatures, pressure from heavy objects, or impacts. This type of damage is more serious and not easily repaired (and could pose safety risks if fixed improperly).

It is recommended to contact the brand’s customer service for professional inspection. In some cases, the heating plate may need to be replaced.

Additional Tips:

To extend the life of your electric pressure cooker and minimize air leakage issues:

• Avoid collisions with the inner pot and lid.

• Do not place heavy objects in the inner pot.

• When cleaning, avoid using hard brushes or scrubbing the sealing ring and inner pot too aggressively.

• After each use, clean and dry the cooker promptly.

Summary:

To troubleshoot air leakage around your electric pressure cooker, follow the steps in the order of: Sealing Ring → Steel Ring → Inner Pot (Shape + Height) → Heating Plate. You can identify and resolve most issues through cleaning, adjustments, or replacing parts. If you are confident in your ability to handle repairs, you can resolve the problem yourself.

If leakage persists after following the inspection steps or if you are unsure how to proceed, it is advisable to contact the brand’s customer service to avoid further damage from self-repair.

www.steamatech.com

STEAMATECH (China) Technology Co.,Ltd