Drill machines are indispensable tools in various industries, ranging from construction and manufacturing to woodworking and metalworking. These versatile devices have evolved over time, giving rise to a wide array of drill machine types, each designed to meet specific needs and applications. In this comprehensive guide, we will delve into the world of drill machines, exploring the different types available and their practical applications.

- Handheld Drill Machines:

Handheld drill machines are the most common and widely used type. They are portable, easy to operate, and suitable for a wide range of drilling tasks. These drills come in various sizes and power options, including corded and cordless models. They are ideal for tasks such as drilling holes in wood, metal, plastic, and even concrete, making them a staple in construction, woodworking, and DIY projects. - Hammer Drills:

Hammer drills, also known as percussion drills, are specifically designed for drilling into hard materials like concrete, masonry, and stone. They feature a hammering action that helps break through tough surfaces while drilling. Hammer drills are commonly used in construction, renovation, and installation projects where drilling into solid materials is required. - Rotary Drills:

Rotary drills are heavy-duty machines primarily used in industrial settings. They are capable of drilling large diameter holes in tough materials such as metal, steel, and concrete. Rotary drills utilize a rotating motion combined with high torque to penetrate hard surfaces efficiently. These drills are commonly found in manufacturing plants, metal fabrication, and construction projects that demand precision and power. - Magnetic Drills:

Magnetic drills, also known as mag drills, are specialized machines used for drilling holes in metal. They feature a strong magnetic base that adheres to the metal surface, providing stability and accuracy during drilling. Magnetic drills are commonly used in metalworking industries, such as fabrication, shipbuilding, and automotive manufacturing. - Drill Presses:

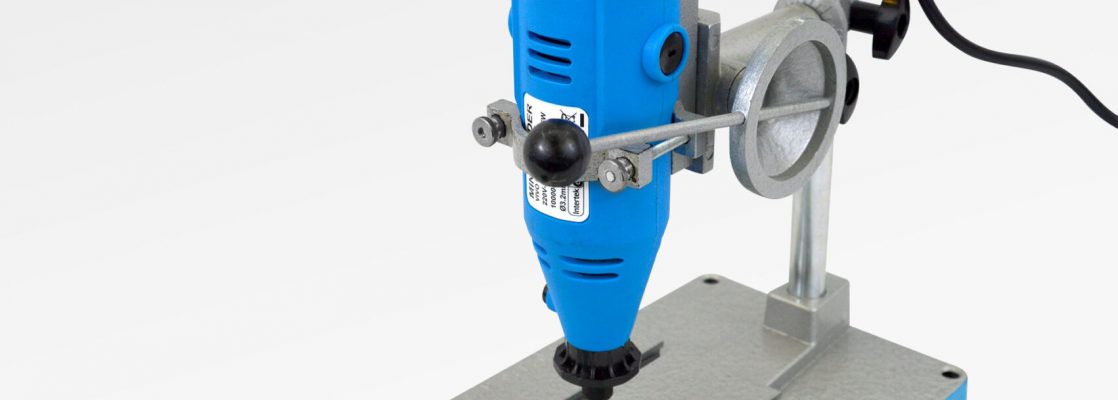

Drill presses, also called bench drills, are stationary machines that offer precise drilling capabilities. They are mounted on a workbench or floor stand and feature a vertical spindle for drilling. Drill presses are commonly used in woodworking, metalworking, and precision engineering, where accuracy and repeatability are crucial.

Conclusion:

Drill machines come in a variety of types, each designed to cater to specific drilling needs and applications. From handheld drills for everyday tasks to specialized machines for industrial applications, the world of drill machines is vast and diverse. Understanding the different types and their applications can help professionals and enthusiasts alike choose the right tool for the job. Whether you are a construction worker, a metal fabricator, or a DIY enthusiast, having the right drill machine at your disposal can significantly enhance your productivity and efficiency. So, explore the world of drill machines, unleash your creativity, and achieve remarkable results in your projects.