Invisible braces (including transparent aligners and clear retainers) have

the advantages of being aesthetically pleasing, comfortable, easy to maintain,

easy to clean, having a short treatment cycle, and being convenient to put on

and take off. They are quickly becoming the preferred alternative to traditional

wire braces. In short, invisible braces are made by processing plastic sheets

through thermoforming on custom 3D-printed dental models.

1. Intraoral Scanning

Before manufacturing transparent dental aligners, the first step is to obtain

the patient's oral data. Usually, a 3D intraoral scanner is used to scan the

patient's mouth, or a desktop 3D scanner is used to scan physical models or

plaster models to obtain 3D digital model data in STL format.

2. Design

Import the scanned digital model files into appropriate orthodontic or dental

computer-aided design (CAD) software (such as 3Shape, Exocad). The design

software includes two main categories: making transparent aligners and making

clear retainers.

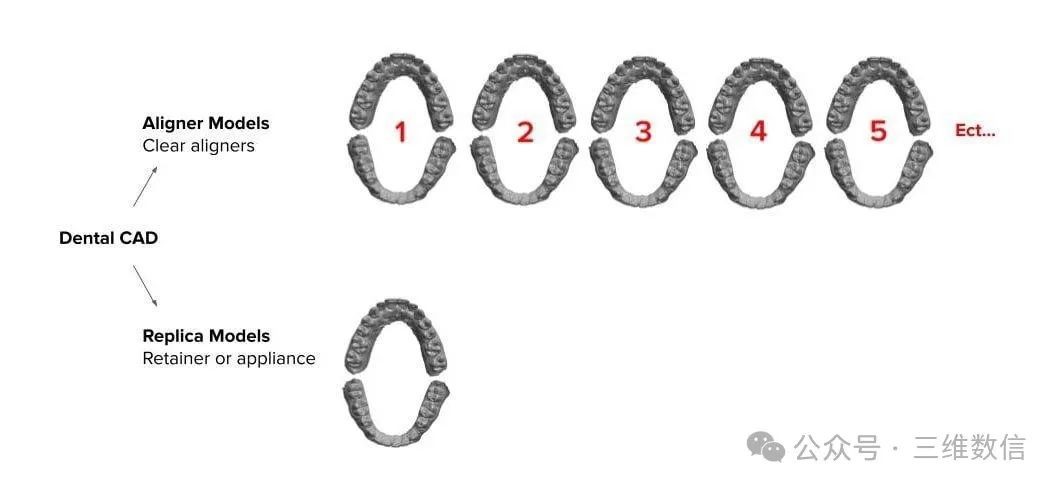

Invisible Aligners

Dentists perform tooth separation, tooth arrangement, animation, and staging

based on the scanned data, communicate with clients to confirm the treatment

plan and schedule, and sometimes use CBCT data for assistance during the

planning stage.

After the treatment plan is finalized, the dental model data for each stage

is output.

Clear Retainers

Retainers are used in the post-treatment phase. To make retainers, only the

scanned dental model data after treatment is needed. Simple operations such as

trimming and filling undercuts are performed in the design software, and

finally, the dental model data is output.

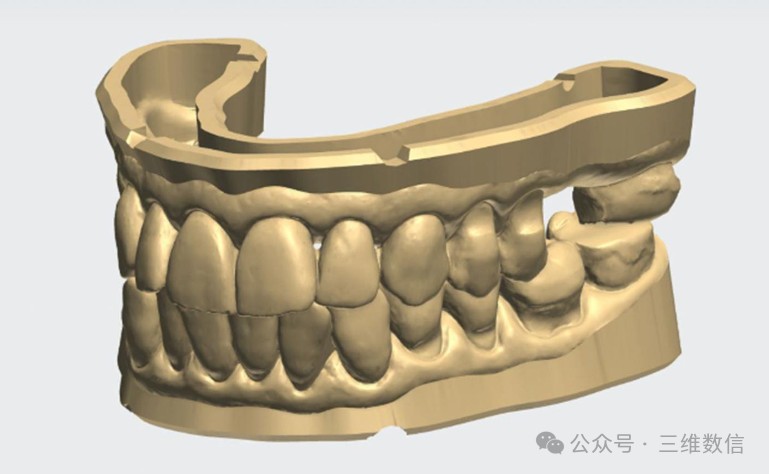

Optional Designs for Dental Model Data

– Hollow Models

To save costs, dental models are usually designed to be hollow, with a wall

thickness generally ensuring no less than 3mm.

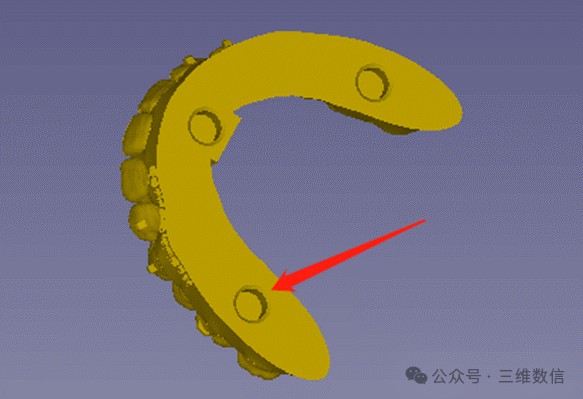

– Through Holes

Hollow models have cavities, which may lead to printing failures. It is

recommended to add through holes at the bottom.

– Honeycomb Filling

To reduce the decrease in overall strength of the hollowed model, honeycomb

structures can be used to fill the hollowed areas.

– Reinforcing Crossbars

To avoid shrinkage and deformation of arch-shaped dental models, crossbars

are added at the opening.

– Fixture Positioning

To match automatic invisible brace cutting machines, positioning holes need

to be added at the bottom of the dental model, with specific shapes referring to

the cutting machine.

– QR Codes

Adding QR codes to the dental model, which can be read by industrial cameras,

enables quick and accurate access to relevant information about the dental

model, realizing automatic identification of dental model information.

– Text Markings

Adding concave or convex text markings on the dental model facilitates later

sorting work and greatly improves work efficiency.

3. 3D Printing

(1) Load the model in the slicing software. Thermoformed dental models are

generally printed directly on trays without supports. Then, select the resin and

parameters to complete slicing.

(2) Upload the sliced data to the printer and complete the printing.

4. Post-Processing of Dental Models

(1) Remove the dental model from the tray.

(2) Place the model in a cleaning machine filled with isopropyl alcohol (IPA,

≥96%) for cleaning. To ensure thorough cleaning, it is usually cleaned

twice.

(3) Take the model out of the IPA and air-dry it in a well-ventilated area at

room temperature or dry it with an air gun.

(4) Put the cleaned and dried model into a curing oven and set appropriate

parameters for post-curing.

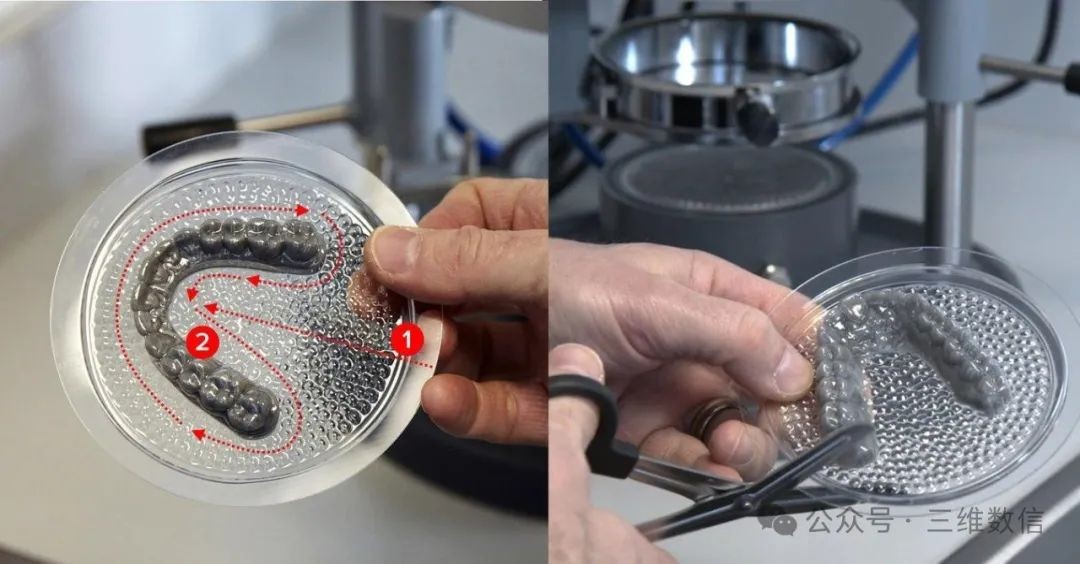

5. Thermoforming

Using the printed model, process the sheets into invisible braces with dental

thermoforming equipment.

6. Laser Marking

Use laser marking on the sheets for easy classification, packaging, and

traceability.

7. Trimming

– Manual cutting

– Automatic trimming

8. Polishing

Cutting or trimming with scissors or dental handpieces can result in sharp

and rough edges. Use grinders and polishers to trim and polish the edges.

9. Quality Inspection

Quality inspection is a particularly important step in the manufacturing

process. The finished products need to be thoroughly inspected to ensure they

are clean and free of defects.

10. Packaging

Classify according to the client and their treatment cycle, and pack the

invisible braces into custom boxes.

www.conversighttech.com

ConverSight