Selecting the right water ring pelletizer system is a critical decision for manufacturers in the plastics and extrusion industries. The efficiency, consistency, and quality of your final product often depend on the pelletizing equipment you choose. With many options available on the market, it is essential to understand what factors to consider to ensure you invest in a solution that meets your unique production requirements.

Understanding Water Ring Pelletizer Systems

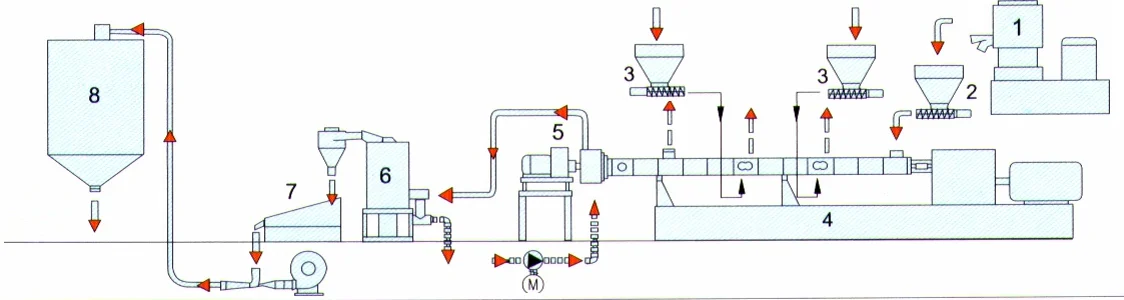

A water ring pelletizer system is widely used in plastic extrusion and compounding processes. It operates by cutting molten polymer strands at the die face, where water immediately cools and transports the pellets. This method is especially suitable for polyolefins, thermoplastics, and other polymers that require consistent pellet size and shape for downstream processing.

The system is popular in industries such as plastic recycling, foam extrusion, compounding, and masterbatch production because of its compact design, continuous operation, and ability to produce uniform pellets with high efficiency.

Key Factors to Consider

1. Material Compatibility

Different polymers have unique melt flow properties, viscosities, and cooling requirements. Choose a water ring pelletizer system designed to handle the specific resins you process—whether it’s PE, PP, PS, ABS, or specialty blends.

2. Production Capacity

Evaluate the throughput of the pelletizer. Systems come in various sizes, ranging from small-scale laboratory models to high-capacity industrial solutions. A mismatch in capacity can either lead to underperformance or unnecessary energy consumption.

3. Pellet Quality Requirements

If your application demands highly uniform pellet size, surface finish, or minimal dust generation, invest in a high-precision system. Consistent pellet quality not only improves downstream processing but also enhances your end product.

4. Ease of Operation and Maintenance

A reliable water ring pelletizer should feature user-friendly controls, easy access for cleaning, and minimal downtime during maintenance. Automated functions, such as self-adjusting cutters, can further reduce operator intervention.

5. Energy Efficiency and Cost-Effectiveness

Energy consumption directly affects your production cost. Modern systems with optimized cooling, advanced cutting technologies, and efficient drive systems can significantly reduce energy usage while maintaining high performance.

6. After-Sales Support and Customization

Consider equipment suppliers who provide comprehensive technical support, spare parts availability, and system customization tailored to your production line.

Why Work with Jiangsu Kaifeng Xinye Intelligent Equipment Co., Ltd.?

Jiangsu Kaifeng Xinye Intelligent Equipment Co., Ltd. is a leading enterprise committed to driving innovation in the machinery industry. With expertise in foam extrusion, plastic compounding, and pelletizing technologies, the company has developed advanced water ring pelletizer systems that meet global manufacturing demands.

Their pelletizers are designed with high efficiency, durability, and intelligent control systems, ensuring reliable performance across diverse industrial applications. By partnering with Jiangsu Kaifeng Xinye, manufacturers gain access to cutting-edge equipment backed by strong technical expertise and service support.

Conclusion

Choosing the right water ring pelletizer system involves balancing material compatibility, production capacity, pellet quality, energy efficiency, and supplier reliability. With the support of experienced manufacturers like Jiangsu Kaifeng Xinye Intelligent Equipment Co., Ltd., businesses can ensure they invest in a solution that not only meets today’s needs but also supports future growth and innovation.

www.kaifengmachine.com

Jiangsu Kaifeng Xinye Intelligent Equipment Co., Ltd.