The application of laser engraving machine in the cultural and handicraft industry is more and more extensive, which has injected new vitality into these two traditional industries. With the continuous progress of technology and the increasing demand for personalization. More and more designers and artists have begun to use laser engraving technology, which can not only improve the precision of the work, but also achieve personalized customization and efficient mass production. The wide application of this technology, laser engraving machine has become an important force to promote the innovation and development of cultural and arts and crafts industry

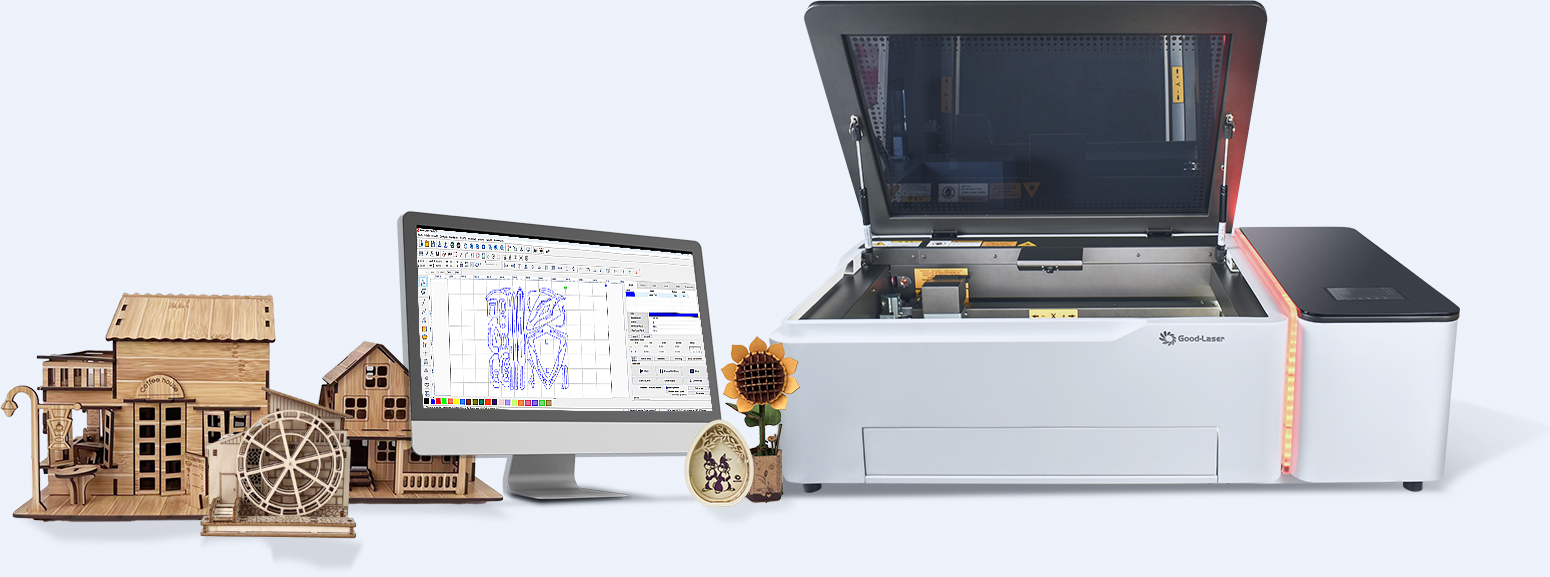

Laser engraving machine through the high-power laser beam focused on the surface of the material, to achieve precise cutting and engraving, can create detailed works of art on a variety of materials. Compared with traditional handicrafts, laser engraving can provide higher precision and more exquisite detail processing. Including wood, leaves, acrylic, glass, leather, ceramics and other non-metallic materials, laser engraving machine can accurately restore the design pattern according to the designer's creativity, so as to achieve more diversified and personalized works.

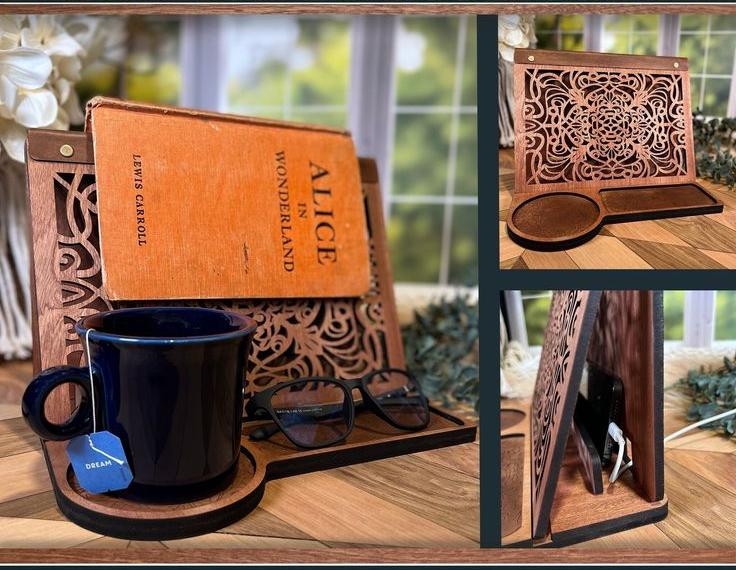

In the design of cultural and creative products, laser engraving machine is widely used in the production of various creative goods, such as customized wooden stationery, personalized mobile phone cases, exquisite home decorations and so on. Through computer control, laser engraving machine can easily achieve complex pattern engraving, even three-dimensional engraving, greatly broadening the imagination of the design space, making the cultural and creative products from appearance to function are more unique.

For the arts and crafts industry, laser engraving technology offers the possibility of high efficiency and customization of production. Traditional hand carving often requires a lot of time and energy, and is prone to inconsistent quality problems in the production process. The laser engraving machine can greatly improve the production speed and consistency while maintaining high precision, ensuring that each product meets the expected standards.

The advantages of laser engraving machine are not only reflected in accuracy and efficiency, but also able to break through the limitations of materials and create more craft works of different materials. In addition to traditional wood and paper, the laser engraving machine also performs well in the processing of plastic, leather, metal, glass and other materials, broadening the application scenario of cultural and handicrafts.

Laser engraving machine can be carved on transparent materials such as glass and ceramics to create exquisite three-dimensional effects and artistic patterns; On the surface of non-metallic materials, the laser engraving machine can produce detailed logos, patterns, text, etc., adding a modern and high-end sense to the handicrafts. The diversity of these materials brings more possibilities to the cultural and creative industry, especially for those who pursue high-quality, unique design consumers, laser engraving provides unlimited creative space.

https://www.good-laseredu.com/

Dongguan Henghao Laser Technology Co., Ltd