Industrial furnace tubes play a critical role in semiconductor and laboratory applications—yet they are constantly exposed to dust, oxide deposits, and production residues. Without proper cleaning, contamination can compromise product quality and equipment life. This is why a high-performance furnace tube cleaning machine is essential for ensuring stable production.

As a trusted provider of contamination-safe plastic equipment for laboratories and the semiconductor industry, Xinruiwei Semiconductor designs tube cleaning machines that offer efficiency, precise control, and reliability in controlled environments.

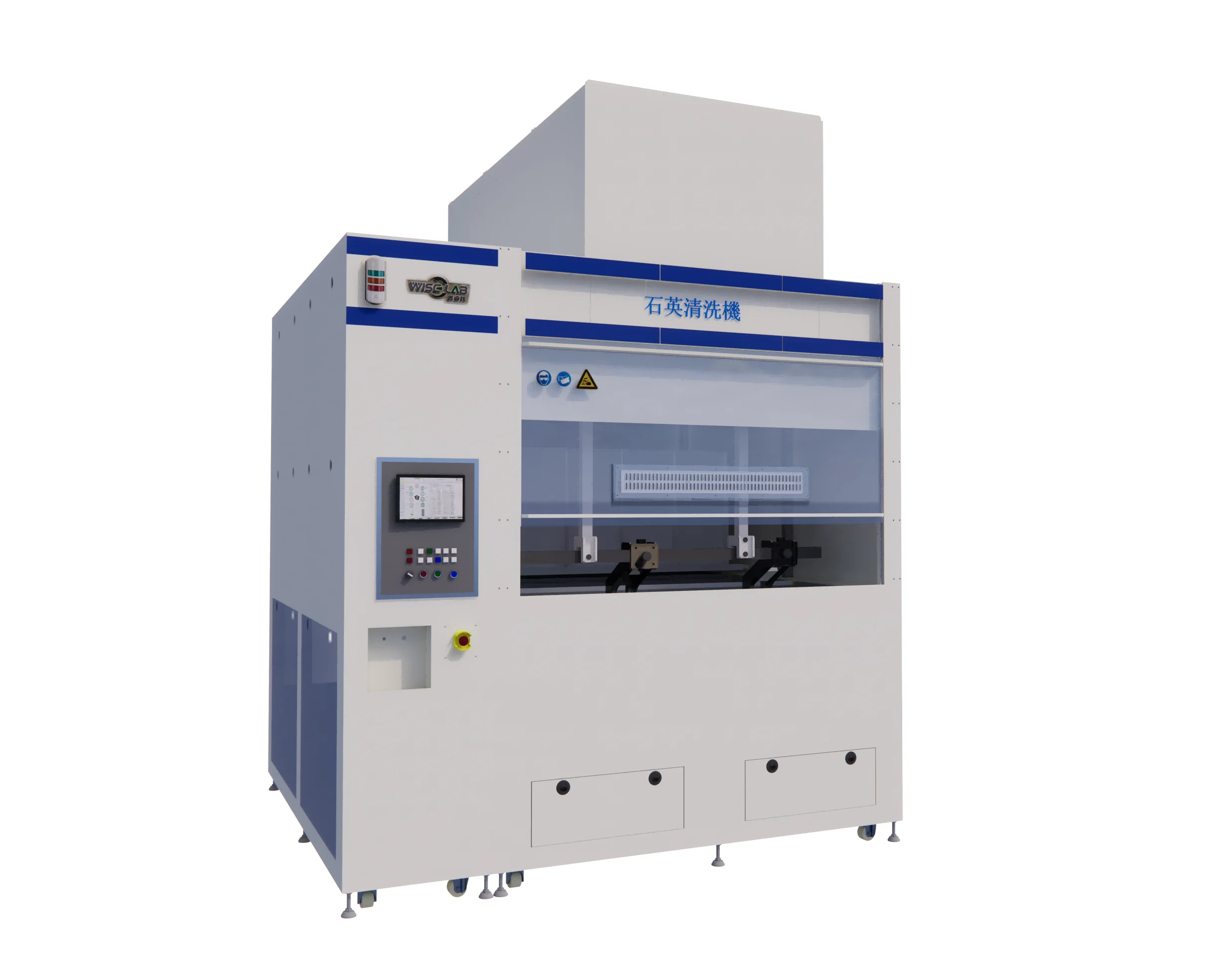

Understanding the Furnace Tube Cleaning Machine

A furnace tube cleaning machine is designed to remove stubborn residues from quartz tubes, reaction chambers, and heating equipment. These systems typically feature:

-

Rotational cleaning heads for uniform internal cleaning

-

Vacuum extraction to collect debris without secondary pollution

-

Anti-corrosion plastic structure ideal for cleanroom environments

-

Digital safety protections to avoid tube scratching or breakage

-

Optional customized fixtures for various tube sizes and materials

With these features, contamination levels are effectively controlled to meet semiconductor-grade production requirements.

Safety Preparations Before Operation

Before starting the cleaning process, always follow these guidelines:

-

Ensure the machine is placed in a stable and ventilated area

-

Verify tubes are fully cooled before cleaning

-

Wear essential PPE such as gloves, goggles, and lab coats

-

Check that the power supply and vacuum system run normally

-

Select the correct cleaning head for the target tube size and hardness

Tip: Always follow contamination-control procedures consistent with cleanroom standards to reduce the risk of impurity introduction.

Step-by-Step Operating Instructions

Here is the recommended cleaning workflow:

Start-Up

-

Turn on the master switch

-

Activate the control panel

-

Select the appropriate mode for the tube type

Tube Installation

-

Fix the tube into the center support base

-

Adjust clamping force to avoid pressure damage

-

Align the cleaning head with the tube entrance

Cleaning Process

-

Gently extend the rotating cleaning tool

-

Monitor cleaning progress through the digital display

-

Activate vacuum extraction to gather particles in real time

-

Once cleaning is complete, retract the cleaning head smoothly

Post-Cleaning Handling

-

Remove the cleaned tube carefully

-

Place it in a dust-free storage area

-

Shut down the machine according to standard operation procedures

This controlled and automated process helps users achieve uniform, scratch-free results.

Maintenance Tips to Extend Equipment Life

Regular maintenance prevents breakdowns and ensures peak performance. Recommended practices include:

-

Clean the vacuum filter and dust collector daily

-

Inspect moving parts and lubrication status weekly

-

Replace worn cleaning heads in a timely manner

-

Avoid moisture exposure to protect electrical systems

-

Schedule periodic calibration to maintain precision

Xinruiwei Semiconductor also offers professional maintenance support and custom plastic solutions to extend the overall service life of your machine and accessories.

Common Troubleshooting Suggestions

| Issue | Possible Cause | Solution |

|---|---|---|

| Reduced suction | Filter or vacuum pipe blockage | Clean or replace filter |

| Scratches on tubes | Wrong cleaning head or misalignment | Adjust position; change brush type |

| Unstable rotation | Lack of lubrication or wear | Lubricate or replace parts |

| Excess noise | Debris stuck inside | Stop machine and fully clear mechanism |

If multiple attempts fail, please contact your equipment provider for technical assistance to avoid further damage.

Why Choose Xinruiwei Semiconductor

-

Specialized in cleanroom-grade plastic equipment

-

Strong R&D for semiconductor and lab environments

-

Customizable tube cleaning solutions

-

Strict quality control for contamination-sensitive industries

Whether you need equipment manufacturing, technical support, or tailored cleaning accessories, Xinruiwei provides reliable, performance-driven solutions.

Conclusion

A furnace tube cleaning machine is essential for maintaining process stability, preventing contamination, and improving yield in semiconductor and laboratory operations. By understanding proper operating methods and following a stable maintenance routine, you can significantly extend tube lifespan and ensure continuous production efficiency.

Xinruiwei Semiconductor is committed to helping customers build safer and cleaner production environments with high-precision plastic equipment.

If you would like expert guidance or equipment customization, our team is always ready to support your success.

www.wafera.com

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd.