In today’s highly competitive manufacturing landscape, precision, efficiency, and flexibility are essential for success. CNC (Computer Numerical Control) machines have become indispensable in industries such as automotive, aerospace, electronics, medical devices, and general engineering. However, the true potential of a CNC machine can only be unlocked with the right CNC machine accessories. These accessories not only enhance the accuracy and productivity of machining processes but also allow manufacturers to customize solutions for specific applications.

Why CNC Machine Accessories Are Essential

While CNC machines provide automated control and high precision, accessories take these capabilities further by:

-

Improving accuracy: Precision tools and holders reduce vibration, ensuring smoother finishes and tighter tolerances.

-

Increasing productivity: Accessories such as tool changers and workholding fixtures streamline operations, reducing downtime.

-

Expanding capabilities: Specialized attachments make it possible to perform milling, drilling, tapping, and turning in one setup.

-

Customization for industries: From small workshops to large factories, CNC accessories can be tailored to meet unique requirements.

In short, CNC machine accessories bridge the gap between standard functionality and advanced custom machining solutions.

Common Types of CNC Machine Accessories

To maximize CNC performance, manufacturers often rely on a wide range of accessories. Some of the most versatile include:

1. Tool Holders and Collets

These are essential for securing cutting tools in place. High-quality tool holders minimize runout and provide better grip, ensuring stable and precise machining. Collets offer flexibility for different tool sizes, making them indispensable in custom machining.

2. Workholding Fixtures

Fixtures, vises, and clamps ensure that workpieces remain stable during machining. Custom workholding solutions can be designed for irregular shapes or delicate materials, reducing waste and improving overall accuracy.

3. Rotary Tables and Indexers

Rotary tables add another axis to CNC machines, allowing for multi-sided machining without repositioning the workpiece. Indexers automate the rotation process, making them ideal for complex parts in aerospace and automotive industries.

4. Coolant Systems

Efficient coolant systems improve tool life, reduce heat, and prevent material distortion. Advanced mist and flood coolant delivery systems optimize cutting conditions, particularly for high-speed machining operations.

5. Tool Changers

Automatic tool changers significantly reduce downtime by quickly switching between different tools. This is especially useful in custom machining solutions where multiple processes are combined in a single setup.

6. Probing Systems

Probing accessories allow CNC machines to automatically measure tool lengths and workpiece positions. This ensures consistent quality and minimizes human error.

Benefits of Using CNC Machine Accessories

By integrating the right accessories into CNC operations, manufacturers gain multiple advantages:

-

Enhanced Precision: Accessories ensure machining tolerances meet exact specifications.

-

Reduced Downtime: Automated systems like tool changers and probes streamline processes.

-

Cost Savings: Better tool life, reduced waste, and improved efficiency lower overall costs.

-

Flexibility in Production: Accessories enable manufacturers to adapt quickly to custom orders.

-

Improved Safety: Proper workholding and coolant systems enhance operator and machine safety.

-

Scalability: Whether for small-batch production or mass manufacturing, accessories support scaling without compromising quality.

Applications Across Industries

CNC machine accessories are widely used across multiple industries, enabling custom machining solutions tailored to unique requirements:

-

Automotive: Precision fixtures and tool changers allow for mass production of engine parts, transmission components, and braking systems.

-

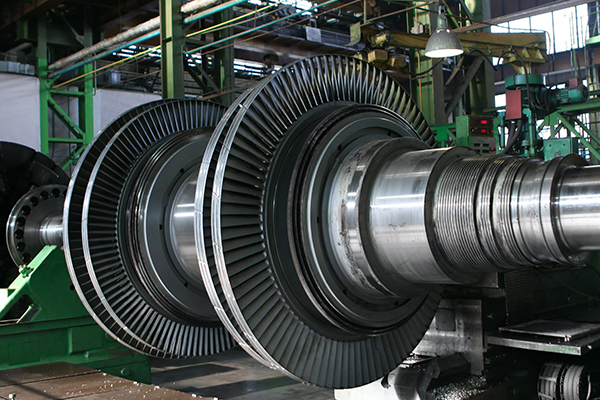

Aerospace: Rotary tables and advanced probing systems are used to create complex, high-strength parts like turbine blades and structural components.

-

Medical Devices: Specialized workholding and micro-tooling accessories ensure the precision needed for implants, surgical instruments, and diagnostic equipment.

-

Electronics: Coolant systems and dust collection accessories support clean machining for delicate circuit boards and casings.

-

General Engineering: Custom accessories adapt CNC machines for diverse applications, from prototyping to mass production.

Conclusion

CNC machine accessories play a critical role in enhancing the performance, versatility, and efficiency of CNC machines. From tool holders and rotary tables to coolant systems and probing devices, the right accessories transform standard machines into powerful tools capable of delivering precise and customized machining solutions. By investing in high-quality CNC machine accessories, manufacturers can optimize productivity, reduce costs, and stay competitive in an increasingly demanding global market.

For businesses seeking versatile CNC machine accessories for custom machining solutions, choosing the right partner and equipment can unlock new levels of efficiency, quality, and innovation.

www.haochengcnctools.com

Jiangxi Haocheng Precision Technology Co., Ltd.