In today’s fast-moving logistics and industrial packaging world, ensuring product safety during storage and transportation is a top priority. Stretch hood packaging—a method using highly stretchable film to tightly secure palletized goods—is gaining popularity due to its efficiency, cost-effectiveness, and superior protection. But at the core of this method is a critical piece of equipment: the Stretch Hood Film Making Machine.

This article will explore what a stretch hood film making machine is, how it works, and why innovative manufacturers like Dostar Packing Equipment Co., Ltd. are driving progress in automated packaging solutions through such advanced machinery.

What Is a Stretch Hood Film Making Machine?

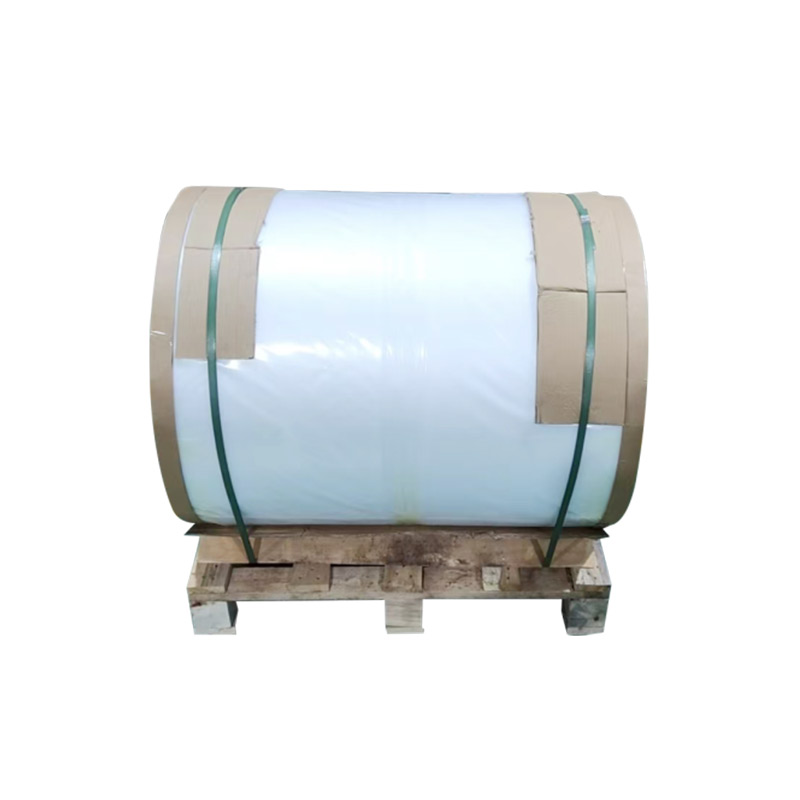

A Stretch Hood Film Making Machine is a specialized production system designed to manufacture highly elastic, multilayer polyethylene (PE) film rolls used in stretch hood wrapping. These films are typically used in automated pallet packaging systems, where the film is stretched and applied over a loaded pallet like a sleeve, offering superior load stability and weather resistance.

This machine is vital for producing films that meet the high-performance demands of sectors like food and beverage, chemicals, building materials, logistics, and warehousing.

Key Functions of a Stretch Hood Film Making Machine

The process of making stretch hood film involves several precise stages, all integrated into one continuous operation. Here's how the machine typically works:

1. Extrusion and Co-Extrusion

At the heart of the machine is the film extrusion system, where raw polyethylene materials are melted and forced through a die to form tubular or flat films. In modern systems, co-extrusion allows multiple layers (often 3–5 layers) to be created simultaneously, combining different material properties such as stretchability, puncture resistance, and UV protection.

2. Bubble Cooling and Sizing

Once the film is extruded, it’s inflated into a bubble and rapidly cooled using an air ring or water-based system. This cooling process helps maintain the film’s structural integrity and clarity.

3. Flattening and Haul-Off

The cooled bubble is collapsed into a flat film using guide rollers and nip rollers. This step ensures that the film maintains a consistent thickness and surface quality.

4. Edge Trimming and Width Control

Precision blades or slitting devices trim the film to exact widths, ensuring the roll matches packaging machine specifications. Width accuracy is crucial for automated stretch hooding systems to work effectively.

5. Winding

The final film is tightly wound into rolls with consistent tension using automated winding systems, ready for use in stretch hood wrapping equipment.

Features of Modern Stretch Hood Film Making Machines

High-performance machines—such as those integrated by Dostar Packing Equipment Co., Ltd.—offer:

-

Multi-layer co-extrusion capability for better film performance

-

Automated thickness and width control for precision and consistency

-

Energy-efficient operation and advanced cooling systems

-

Integrated quality inspection systems to monitor optical clarity, elasticity, and strength

-

Compatibility with both small-scale and high-output film production needs

Why It Matters: The Role of Dostar Packing Equipment Co., Ltd.

Dostar Packing Equipment Co., Ltd. is a high-tech enterprise focused on developing, integrating, and manufacturing automated packaging production lines, including equipment used in the production of stretch hood films.

By offering both semi-automatic systems and fully automated packaging lines, Dostar helps businesses:

-

Improve packaging efficiency

-

Reduce labor and operational costs

-

Enhance load stability and appearance

-

Minimize material waste with precision film application

Dostar's expertise doesn't stop at machinery—they offer turnkey solutions, from stretch hood film production to film application on palletized loads, ensuring clients have a complete and optimized packaging process.

Conclusion

The stretch hood film making machine is a cornerstone of modern pallet packaging systems, enabling the production of flexible, durable, and protective films tailored to the demands of industrial logistics. Understanding how this machine works—and what to look for in a high-quality system—can help manufacturers and distributors gain a competitive edge.

With experienced providers like Dostar Packing Equipment Co., Ltd., businesses gain access to both the equipment and technical expertise needed to optimize every stage of the packaging process—from film manufacturing to automated end-of-line solutions.

For companies seeking greater efficiency, safety, and sustainability in their packaging operations, investing in stretch hood film making technology is a smart move into the future of industrial automation.

www.dostar-pack.com

Dostar Packing Equipment (Wuxi) Co., Ltd