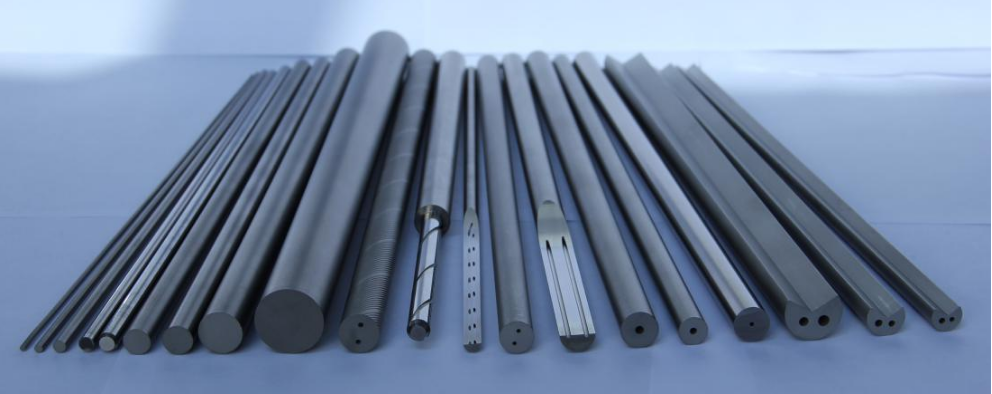

Solid carbide rods are the foundation of many high-precision cutting tools and industrial components. Known for exceptional hardness, wear resistance, and heat tolerance, they are widely used in demanding environments where conventional steel fails to deliver required performance. As advanced manufacturing technologies continue to grow, solid carbide materials play an increasingly important role in efficiency, accuracy, and long-term durability.

Among trusted providers in this field, Shanghai Diatooling stands out as a professional and experienced manufacturer and supplier of carbide cutting tools. With strong engineering capability and strict quality standards, the company supports customers across automotive, aerospace, electronics, and mold-machining industries.

Versatility and Material Advantages

Solid carbide rods combine the strength of tungsten carbide with engineered binding metals, enabling:

-

Outstanding hardness for long tool life and stable machining

-

High thermal resistance for high-speed cutting conditions

-

Dimensional stability for precision machining

-

Excellent abrasion resistance in harsh environments

These properties make carbide a preferred choice for tools that must consistently perform under extreme stress.

Essential Role in CNC Machining

Carbide rods are widely used to produce end mills, drill bits, reamers, and other CNC cutting tools. In modern CNC operations, machining accuracy is directly linked to material stability and spindle speed performance.

Carbide-based tools enable:

-

Faster cutting speeds with less tool deformation

-

Superior surface finishes, reducing secondary polishing

-

Longer tool lifetime, cutting down on tool change delays

-

Improved machining of hard alloys and composite materials

Shanghai Diatooling supplies a wide range of carbide rods designed for toolmakers seeking high performance, from micro-diameter cutters to heavy-duty machining tools.

Precision Machining in the Mold and Die Industry

The mold and die sector demands exceptional surface quality and tolerance control. Carbide rods offer:

-

High rigidity for deep cavity machining

-

Consistent edge sharpness for finishing operations

-

Smooth cutting with reduced vibration

These characteristics help manufacturers maintain productivity while ensuring mold longevity and product accuracy.

Growing Demand in Electronics Manufacturing

As consumer electronics become smaller and more complex, tiny and high-precision tools are essential. Solid carbide rods support the production of:

-

Micro drills for PCBs

-

Fine milling tools for metal and plastic casings

-

Cutting tools for semiconductor components

Stable carbide performance allows mass production with lower scrap rates and higher throughput.

High-Performance Applications in Aerospace

Aerospace parts are often made from titanium, Inconel, stainless steels, and carbon fiber—materials that are notoriously difficult to machine. Solid carbide rods enable machining that meets strict aerospace specifications by offering:

-

Strength retention at high cutting temperatures

-

Longer wear life versus high-speed steel alternatives

-

Consistent accuracy for safety-critical components

Whether manufacturing turbine blades, landing gear parts, or structural elements, carbide-based tools ensure reliability under pressure.

Supporting Innovation and Productivity

Solid carbide rods not only improve tool reliability—they directly drive productivity, cost-effectiveness, and innovation in next-generation manufacturing. As new materials emerge and machining challenges increase, carbide will continue to be a critical pillar of precision engineering.

With years of industry experience and a complete product portfolio, Shanghai Diatooling delivers high-quality carbide rods and custom tooling solutions for global customers. By providing stable supply, strict inspection, and expert technical support, the company enables manufacturers to achieve greater machining performance and competitive advantage.

Conclusion

From CNC machining workshops to aerospace production lines, solid carbide rods are indispensable to the growth of advanced manufacturing. Their mechanical superiority, durability, and precision capabilities make them the ideal choice for industries that demand the highest level of performance.

Whether you are a toolmaker, machine shop operator, or industrial engineer, partnering with a trusted supplier such as Shanghai Diatooling ensures access to reliable carbide materials tailored to your application needs.

https://www.diatooling.com/

Shanghai Diatooling