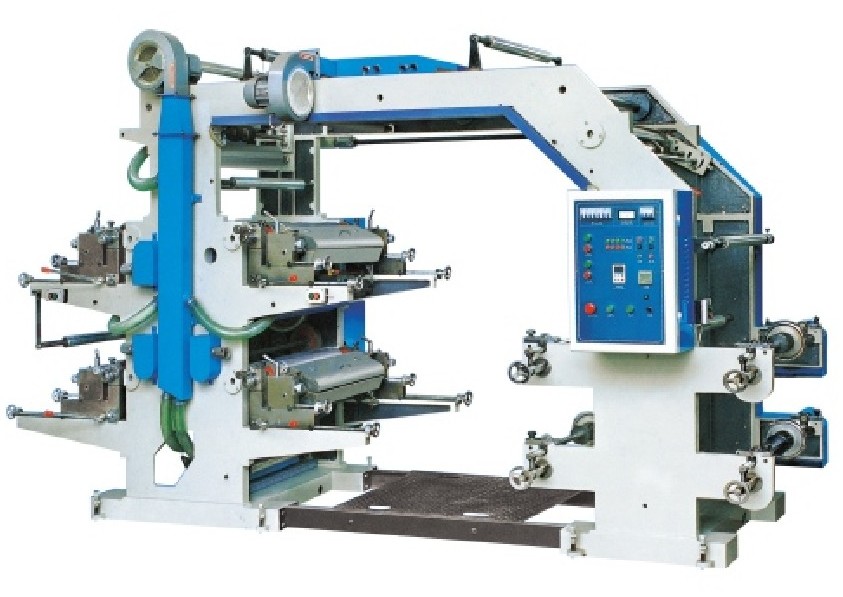

Label printing equipment is suitable for label printing of various types and materials. Among them, heat shrinkable film label printing equipment is the most common. Because the heat shrinkable film is a kind of thermoplastic film that is stretched and oriented during the production process, and shrinks by heat during use. Therefore, no matter which printing method is used for printing, before the design of the surface pattern, the horizontal and vertical shrinkage of the material, as well as the allowable deformation error in each direction of the decorative graphic and text after shrinking, can be taken into account to ensure that the pattern, Accurate restoration of text and barcode. The following will introduce the bar code placement precautions when using label printing equipment for printing.

1. Generally, the placement direction of the barcode must be consistent with the direction during printing, otherwise the lines of the barcode will be distorted, which will affect the scanning result and cause misreading.

2. In addition, the color selection of label products should be based on spot colors as much as possible, and the production of white version is necessary, which can be made into full or hollow according to the actual situation.

3. The color of the barcode must follow the general requirements, that is, the color matching of the bar and the space must comply with the principle of barcode color matching.

In addition to controlling the printing process, the printing materials used in label printing equipment play a decisive role in affecting label quality. Therefore, choosing the right printing material is the key.

Determine the thickness of the film material according to the application field and cost of the heat shrinkable label, the characteristics of the film, shrinkage performance, printing process and labeling process requirements. It is generally required that the film thickness of the shrink film label should be 30 microns-70 microns, with 50 microns, 45 microns, and 40 microns more commonly used, depending on the labeling performance of the label printing equipment.

For the selected label materials, the shrinkage rate of the film material is generally required to be within the application range, and the transverse (TD) shrinkage rate is higher than the longitudinal (MD) shrinkage rate. The transverse shrinkage rate of commonly used materials is 50%?52% and 60%?62%, and can reach 90% under special circumstances. The longitudinal shrinkage rate is required to be 6% to 8%. In addition, since shrink film is very sensitive to heat, high temperatures must be avoided during storage, printing, and transportation.

Danis is a label printing equipment supplier, with various models and types of label printing equipment for sale. If you want to know more about the barcode placement rules of heat shrink label printing equipment, please consult us.

Tag: label printing equipment supplier, label printing equipment for sale, heat shrink label printing equipment

tony

45241430@qq.com